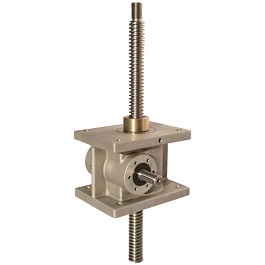

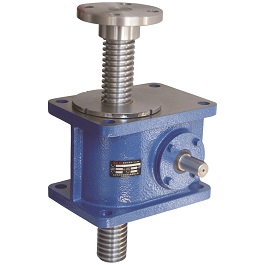

MA series trapezoid spiral screw jacks

Cone enveloping tooth profile: worm gear screw jacks

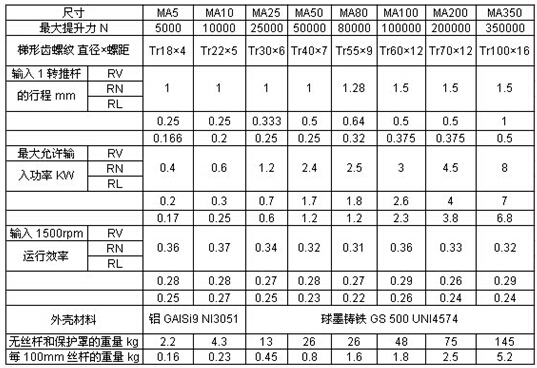

Bearing standard is from 0.25 tons to 250 tons.

Up or down, left and right sides: movement type of screw and nut.

It has two kinds of gear ratio and one standard screw and multihead screw.

It has the option of backlash device and anti-reverse device (keying).

6 kinds of fixed way, including Trunnion fixed and double flat head fixed.

Special customized according to customer needs: All non-standard.

Considering the condition of application, and then choose suitable products.

If you need us to choose more suitable product for you, please provide us the parameter as follows:

1. Weight of Jacks: how much Kg?

2. Speed of Jacks: the moving length of the screw or screw nut per minute or per second.

3. Screw movement form: screw move or screw nut move.

4. One or several device for jacks.

5. Whether directly connect with drive motor?

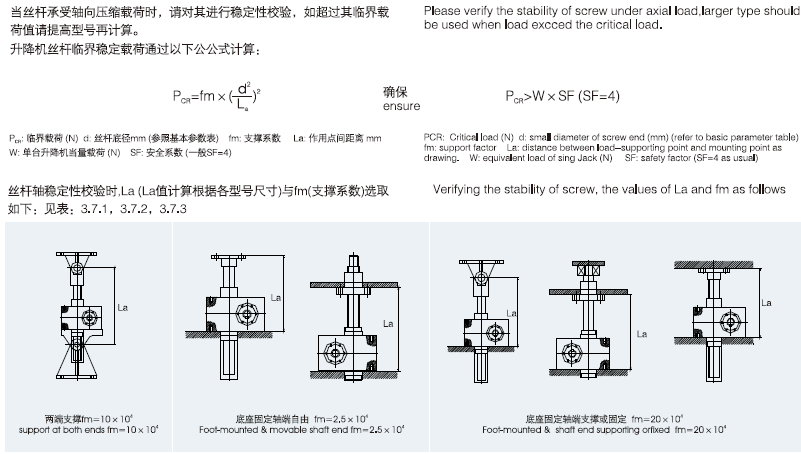

Important calculation: calculation for the root diameter of screw.

Modify the standard spiral screw jack

Suitable modify parts including non-standard coating(passivation treatment: galvanize, chroming, equip with 2-nipple or 3-nipple thread screw and stainless steel screw or worm shaft , improve the length of screw shaft and worm shaft, and furnish with reverse thread screw and so on

Adding and changing accessories for standard spiral screw jacks.

It can add accessories, such as: safety lock nut, anti-reverse device, special screw nut, coding adapter flange, non-standard motor flange and so on.

Completely special screw jacks

We can’t change the existing screw jacks, but we can design and manufacture according to your special need.

1. Several spiral screw jacks can be linked to be a lifting system. It can start with several screw jacks in the same time. There are some patterns for this kind of lifting system, they are need to be equipped with bevel gearbox, motor, reducer, drive shaft, coupling and movement control device. All accessories can refer to the system parts.

2. H type and U type lifting structure is two commonly used system structures.

3. Please note, several screw jacks can be mechanical linked and electric linked.

Electric linked is used for the condition with no spare space to connect drive shaft, if connect several screw jacks to be a lifting system, you need to consider the self-locking of the whole system. Relative questions can consult Beijing Saili Transmission Co., Ltd, or add a brake device for the system, this device is independent and also can be a brake motor.